The Best Liquid Level Sensors for Industrial Applications: Accurate, Safe, and Reliable Monitoring

In industrial environments, precise liquid level measurement is essential for safety, efficiency, and compliance with regulations. Whether managing hazardous chemicals, water, or food-grade liquids, industries rely on liquid level sensors to monitor, control, and maintain processes effectively. Icon Process Controls, a leader in industrial instrumentation, offers some of the best liquid level sensors designed to meet rigorous safety and operational demands.

This blog explores the importance of choosing the right liquid level sensor, emphasizes the significance of double-walled tank leak detection sensors, and highlights why Icon Process Controls’ solutions are trusted across industries. Additionally, we provide user-generated insights to foster an engaging, helpful platform aligned with Google’s emphasis on delivering relevant, user-focused content.

Why Liquid Level Sensors Are Crucial for Industrial Safety and Efficiency

Accurate level monitoring helps industries prevent leaks, spills, and equipment damage. Here are the key reasons why liquid level sensors are indispensable:

Ensuring Workplace Safety

Industries handling hazardous chemicals face constant risks of overflows, leaks, or low liquid levels. Without reliable monitoring, accidents can occur, endangering workers. Liquid level sensors act as a proactive safety measure, alerting operators to potential hazards in real time.

Protecting the Environment

Strict environmental regulations, such as those enforced by the EPA and OSHA, mandate spill prevention and safe chemical management. Liquid level sensors help facilities stay compliant by detecting potential issues before they escalate, preventing contamination of soil and water.

Optimizing Operations and Reducing Costs

Unmonitored levels can lead to waste, production delays, and equipment damage. Sensors ensure precise control, reducing downtime and operational inefficiencies. By maintaining accurate measurements, companies avoid costly repairs, fines, and resource waste.

Enhancing Regulatory Compliance

The Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) have strict standards for storing hazardous substances. Liquid level sensors provide the real-time data facilities need to demonstrate compliance with these regulations, avoiding fines and legal complications.

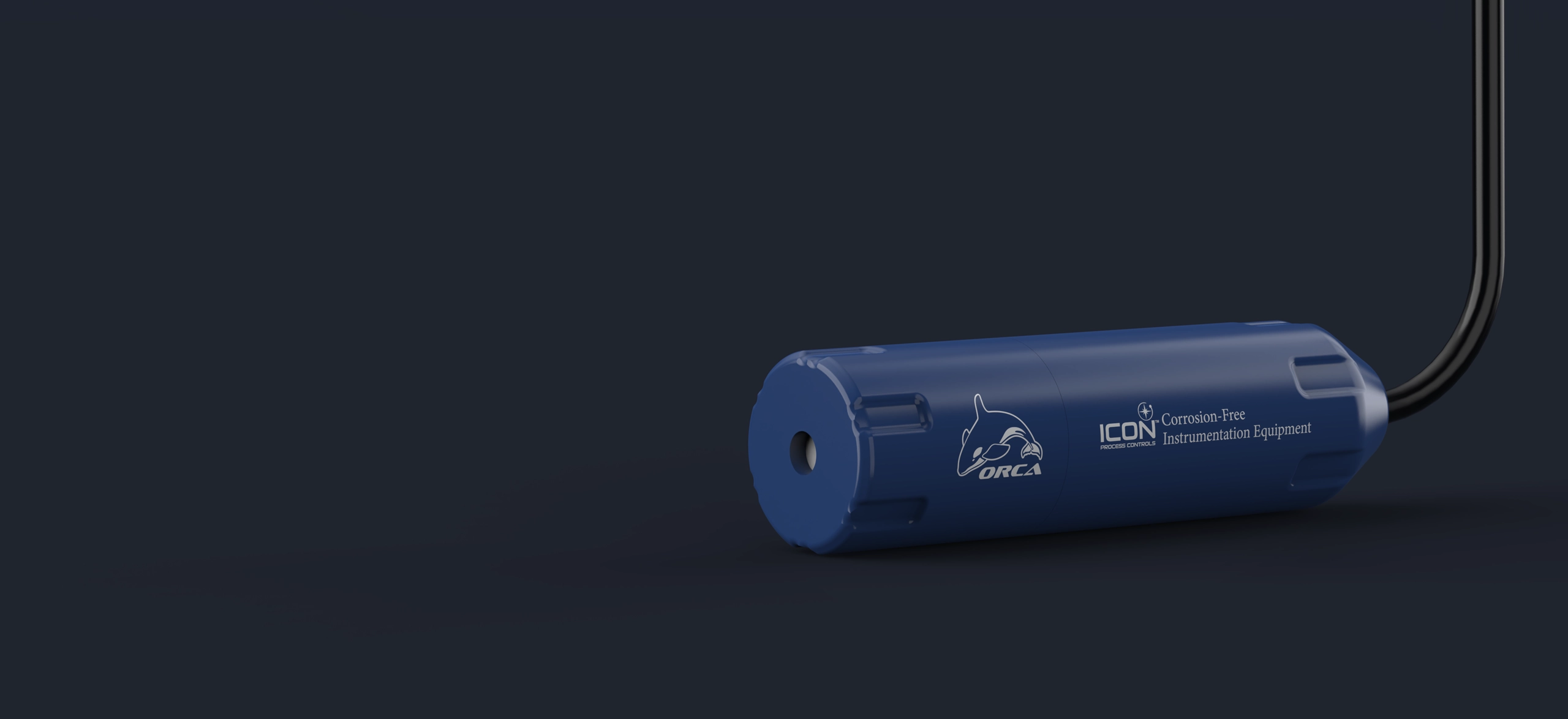

Icon Process Controls: Leaders in Liquid Level Monitoring

Icon Process Controls specializes in innovative liquid level sensors designed for industrial environments. Their products offer unparalleled accuracy, durability, and versatility.

Key Features of Icon’s Liquid Level Sensors

High Precision and Accuracy

Icon’s sensors deliver precise, real-time readings, ensuring efficient control of processes. Whether used in chemical tanks or water reservoirs, their sensors maintain reliable accuracy.

Chemical Resistance and Durability

Constructed from robust materials like PVDF, polypropylene, and stainless steel, Icon’s sensors resist corrosion and handle harsh industrial environments effectively.

Versatile Technologies

Icon offers a wide range of sensor types, including:

- Submersible Sensors — Completely unaffected by Foam, Vapor, Turbulence, and Condensate. Leading to an accurate reading in any environment.

- Ultrasonic Sensors for non-contact measurement.

- Float Sensors for straightforward, reliable monitoring.

- Radar Sensors for highly accurate readings in challenging conditions.

This variety ensures compatibility with different tank sizes, liquid types, and industrial needs.

Real-Time Monitoring and Alerts

Equipped with digital outputs, Icon’s sensors integrate seamlessly with control systems, providing instant alerts when levels deviate from the norm. This allows for quick corrective actions, minimizing risks and downtime.

Double-Walled Tank Leak Detection Sensors: Why They Matter

In industries handling hazardous chemicals, double-walled tanks provide an extra layer of protection by containing leaks within a secondary wall. However, without leak detection sensors, these tanks can fail silently, leading to catastrophic spills.

Why Double-Walled Tank Leak Detection Sensors Are Critical

- Early Leak Detection

Leak detection sensors identify small leaks early, preventing them from escalating into major safety and environmental issues. - Enhanced Safety

By containing leaks, these sensors protect workers, equipment, and the surrounding environment from exposure to dangerous substances. - Regulatory Compliance

Double-walled tank sensors ensure facilities meet OSHA and EPA regulations, avoiding costly fines and demonstrating a commitment to safety.

Icon’s Double-Walled Tank Sensors: Features and Benefits

Icon’s double-walled tank leak detection sensors are designed for high accuracy and reliability. These sensors detect changes in pressure or liquid levels between the tank walls, offering instant alerts. Their durability and ease of installation make them a practical choice for industries requiring continuous safety monitoring.

Real-World Applications and User Experiences

Applications for Icon’s Liquid Level Sensors

Chemical Processing

Icon’s sensors monitor corrosive chemicals accurately, ensuring safe storage and efficient use.

Water Treatment

Their sensors ensure proper flow rates and levels in treatment plants, improving efficiency and water quality.

Food and Beverage

With food-grade materials, Icon’s sensors help maintain consistency and safety in production lines.

Industrial Manufacturing

Accurate level monitoring supports consistent product quality and optimized resource usage in manufacturing.

User Insights: What Customers Say

Hearing from users provides real-world insights into the value of Icon’s sensors:

- Jennifer L., Plant Manager in Chemical Manufacturing:

“Since installing Icon’s liquid level sensors, we’ve significantly reduced overflows and downtime. The real-time alerts are a game-changer.” - Tom R., Environmental Compliance Officer:

“Icon’s double-walled tank sensors have helped us meet EPA standards. Their accuracy and durability make them essential for our safety protocols.” - Samantha T., Operations Manager in Food Processing:

“We rely on Icon’s sensors to maintain product quality. They’re easy to install and require minimal maintenance, saving us time and money.”

Discussion Prompts: Share Your Insights

Engaging users in discussions encourages interaction and builds trust. Consider these prompts to foster community engagement:

- What challenges have you faced with liquid level measurement in your industry?

- How have level sensors improved safety or efficiency in your operations?

- Which features do you prioritize when selecting a liquid level sensor?

These discussions not only provide valuable insights but also help new users make informed decisions.

Why Icon’s Liquid Level Sensors Are the Best Choice

Choosing the right liquid level sensor is a critical investment for any industry managing liquids. Icon Process Controls offers solutions that prioritize safety, precision, and durability. Whether you’re monitoring hazardous chemicals or ensuring water flow in treatment plants, their sensors deliver reliable, real-time performance.

Benefits of Choosing Icon Process Controls

Unmatched Accuracy

Icon’s sensors provide precise measurements, critical for process control and compliance.

Long-Term Durability

Designed to withstand harsh conditions, Icon’s sensors offer exceptional performance with minimal maintenance.

Enhanced Safety and Compliance

With features like double-walled tank leak detection, Icon ensures your facility meets safety and environmental standards.

Conclusion: The Best Solution for Liquid Level Monitoring

Liquid level sensors are essential for maintaining safety, efficiency, and compliance in industrial operations. Icon Process Controls offers industry-leading sensors that address the challenges of liquid monitoring with precision and reliability.

From chemical storage to food production, their sensors deliver real-time data, reducing risks and improving operational performance. With user-friendly designs, durable construction, and regulatory compliance features, Icon’s sensors are the best choice for industries seeking safe and efficient liquid management.

By investing in Icon’s liquid level sensors, industries can enhance safety, reduce costs, and ensure smooth, compliant operations. Explore Icon Process Controls’ offerings today to experience the difference their innovative sensors can make.