In industries that rely on liquid storage, monitoring tank levels is crucial for ensuring safety, compliance, and operational efficiency. Traditional tank monitoring methods, often manual or wired, are being replaced by advanced wireless remote tank level monitoring solutions. Sentinel Telemetry Tank Level Sensors from Icon Process Controls offer cutting-edge wireless monitoring that optimizes inventory management, […]

Blog

Types of Liquid Level Sensors

Discover how liquid level sensors improve precision in industries like water treatment, chemical processing, and food production. Learn more about radar, ultrasonic, submersible, and float sensors from Icon Process Controls.

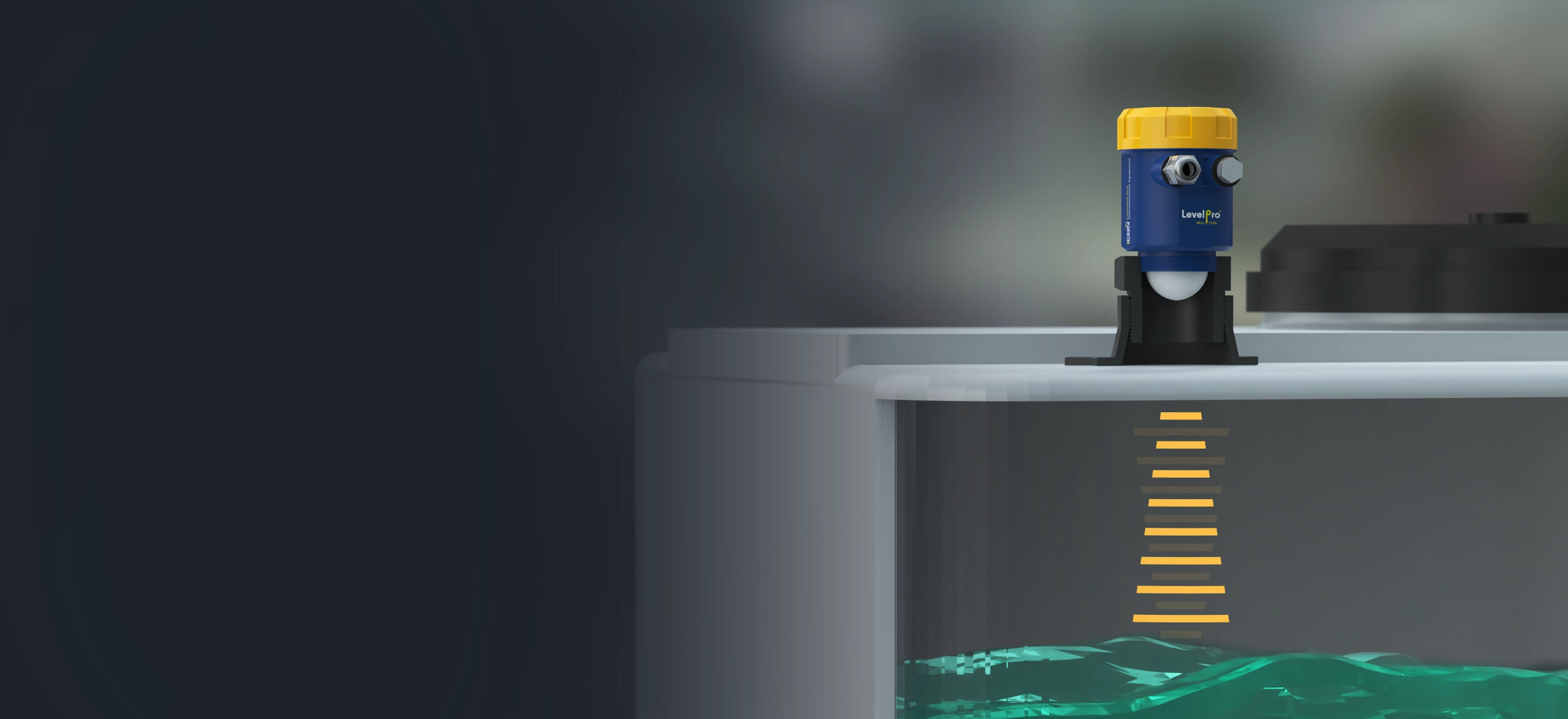

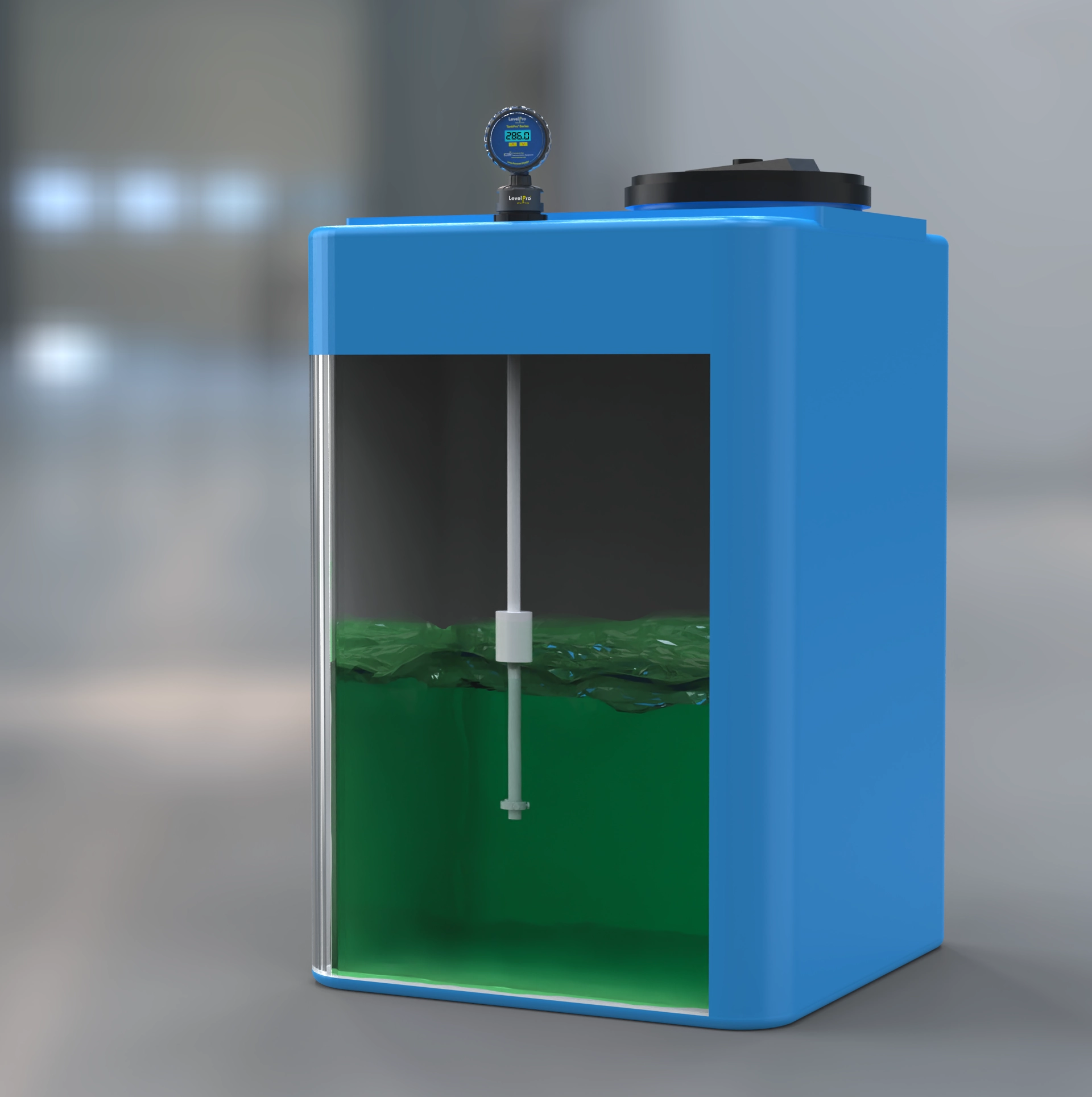

Best Bulk Chemical Level Sensors: Ensuring Safety and Efficiency with Icon Process Controls’ LevelPro Series

Managing bulk chemical storage requires precise, reliable, and durable chemical level sensors to ensure safety, optimize operations, and maintain compliance. Icon Process Controls’ LevelPro series, including the LevelPro 100 Series submersible sensor and the ProScan3 80G radar sensor, meets these demands with advanced technology and robust designs. This blog highlights why liquid level sensors are […]

LevelPro Liquid Level Switches by Icon Process Controls: Key Models and Features

LevelPro liquid level switches by Icon Process Controls ensure precise and reliable tank monitoring in demanding environments. These switches are designed for chemical storage, wastewater management, and other industrial applications. With corrosion resistance and customizable settings, they provide dependable performance for critical operations. Key Models and Their Features PLF Series Liquid Level Switch The PLF […]

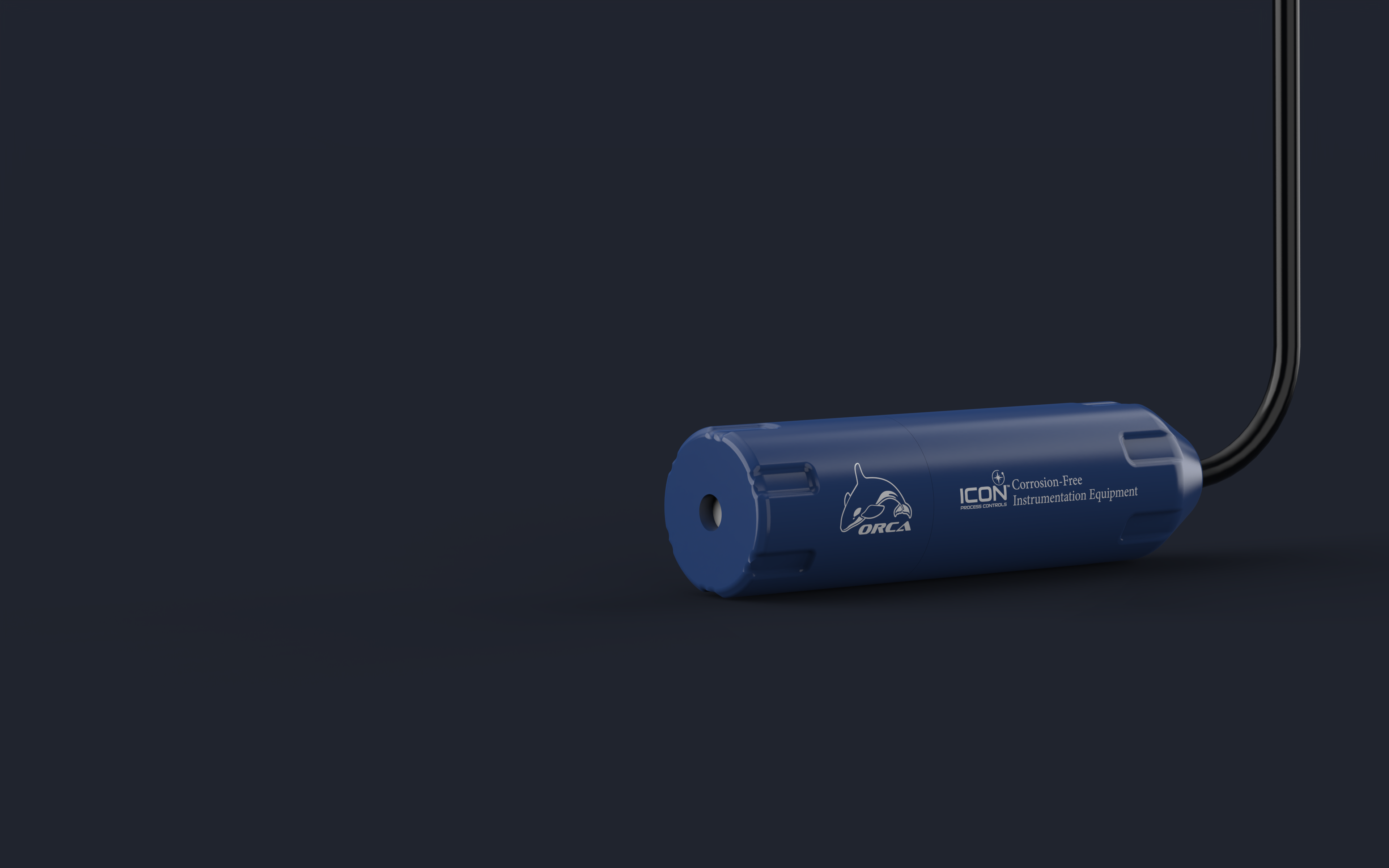

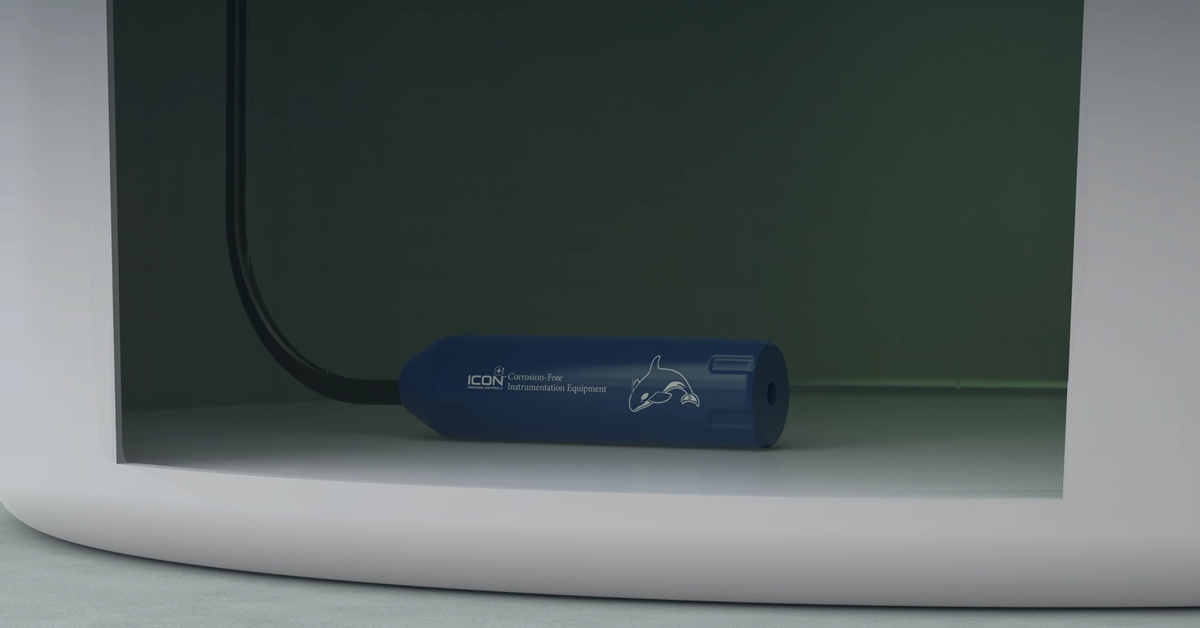

LevelPro Brine Liquid Level Sensors from Icon Process Controls: Key Models and Features

LevelPro liquid level sensors, including the LevelPro 100 Series and ProScan 3 radar sensors, ensure reliable brine tank monitoring with advanced wireless technology.

How to Monitor the Level of a Chemical Tank: An Introduction

Learn about five reliable chemical tank level monitoring methods, including pressure, float, ultrasonic, radar sensors, and visual inspection. Choose the best solution with Icon Process Controls.

The Importance of Wireless Remote Tank Level Monitoring with Sentinel Telemetry

Wireless remote tank monitoring ensures safety, compliance, and efficiency. Discover how the Sentinel Telemetry Sensor transforms industrial operations with real-time insights.

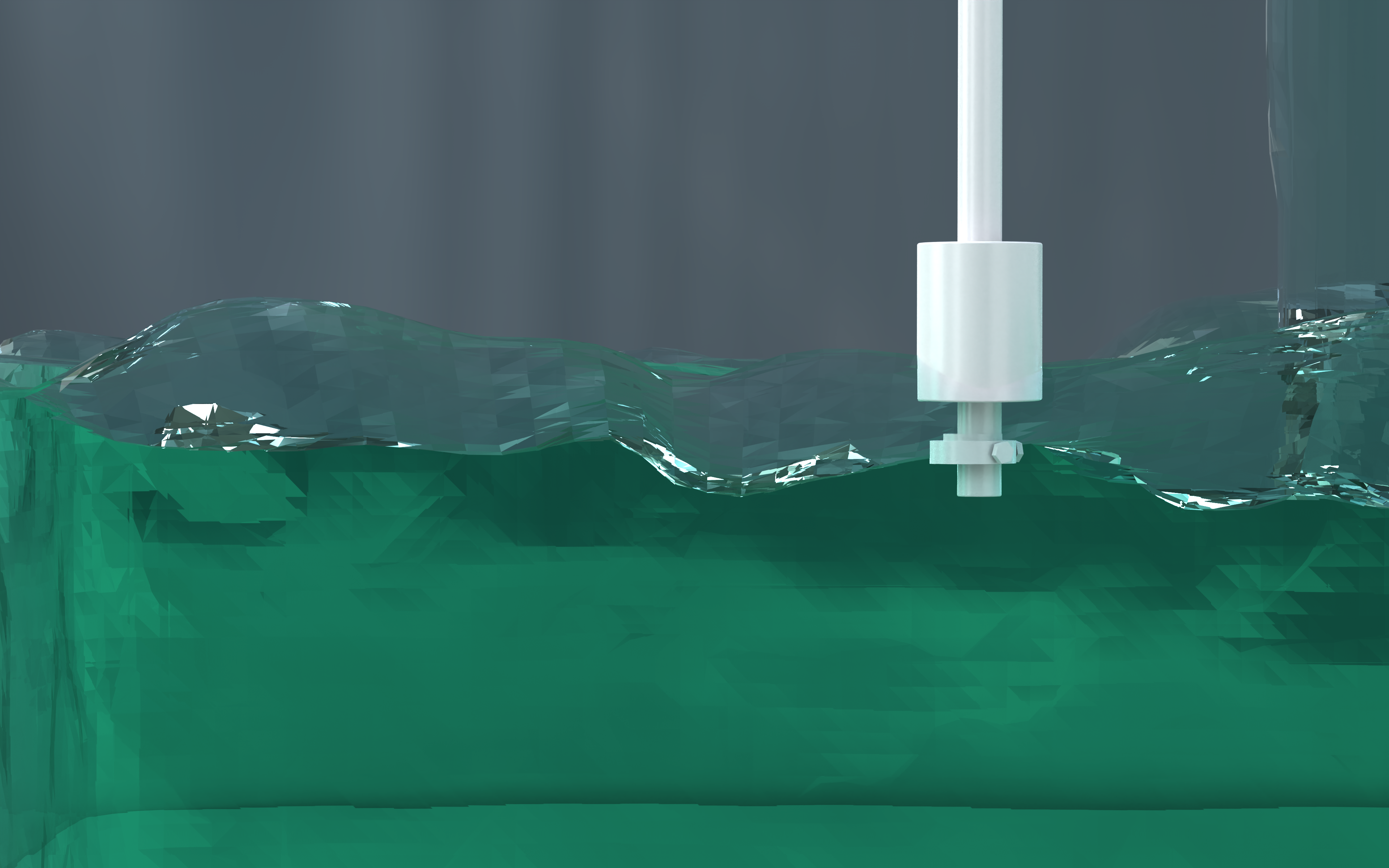

A Complete Guide to Liquid Level Sensors

Efficient liquid monitoring is essential for ensuring safety, maintaining process efficiency, and meeting regulatory standards in industrial operations. Liquid level sensors play a critical role in this by providing accurate, real-time data for various applications. This blog explores liquid level sensors, highlights their types and applications, and explains why Icon Process Controls is a leading […]

Comprehensive Guide to Mining Liquid Level Sensors

Mining liquid level sensors are essential for maintaining operational safety, efficiency, and environmental compliance in mining and metals processing. These sensors monitor liquid levels in tanks, reservoirs, and containment areas for processes like ore refinement, slurry management, and chemical storage. Accurate monitoring ensures consistent operations, reduces downtime, and prevents costly spills or overflows. In mining, […]