Agricultural Liquid Level Sensors — What You Need To Know

Agricultural liquid level sensors play a vital role in modern farming by improving efficiency, safety, and sustainability. Specifically, from irrigation systems to fertilizer tanks, precise liquid level measurement ensures optimal resource utilization and protects against costly overflows or leaks. Additionally, as farms integrate advanced technologies to meet increasing global food demands, reliable agricultural liquid level sensors have become indispensable.

In agriculture, liquid level sensors monitor water, chemicals, and fertilizers stored in tanks, reservoirs, and delivery systems. Moreover, accurate measurements help prevent environmental contamination, minimize waste, and maintain regulatory compliance. These sensors also support automation. Consequently, allowing farmers to focus on maximizing crop yields while ensuring environmental stewardship.

Icon Process Controls leads the industry with a range of advanced agricultural liquid level sensors. Designed for durability, accuracy, and ease of use, these sensors cater to the unique needs of farming operations. From submersible sensors to wireless monitoring systems, Icon’s innovative solutions enable smarter farming practices. This blog explores the features, benefits, and applications of these indispensable tools.

Understanding Agricultural Chemical Liquid Level Sensors

Agricultural chemical liquid level sensors detect and measure liquid levels in tanks, reservoirs, and storage systems. Specifically, they ensure precise monitoring of water, fertilizers, and pesticides. Furthermore, these sensors help farmers optimize resource management, improve safety, and enhance productivity. Advanced materials resist corrosion from harsh chemicals. Thus, ensuring long-term performance in demanding environments.

Importance of Accurate Liquid Level Monitoring

Accurate monitoring is essential for preventing overflows, leaks, and contamination. It ensures efficient water and chemical usage. Hence, reducing waste and operational costs. Regulatory compliance is another critical aspect, as authorities require accurate reporting of chemical storage and usage to protect the environment. Liquid level sensors enhance automation. Therefore, providing real-time data to optimize farming operations.

Icon Process Controls: A Leader in Liquid Level Sensing Technology

Icon Process Controls offers state-of-the-art agricultural liquid level sensors designed to meet modern farming challenges. Their sensors are built with high-quality, corrosion-resistant materials like PVC, PP, PVDF, and PTFE Teflon®. These durable sensors withstand harsh chemicals and extreme conditions. Thus, ensuring reliable performance. Icon’s solutions include wireless technology for seamless integration and remote monitoring. Therefore, making them ideal for diverse agricultural needs.

Types of Liquid Level Sensors Offered by Icon Process Controls

Submersible Level Sensors:

These sensors measure continuous levels in tanks and reservoirs. Hence, they are ideal for liquids prone to turbulence or foam.

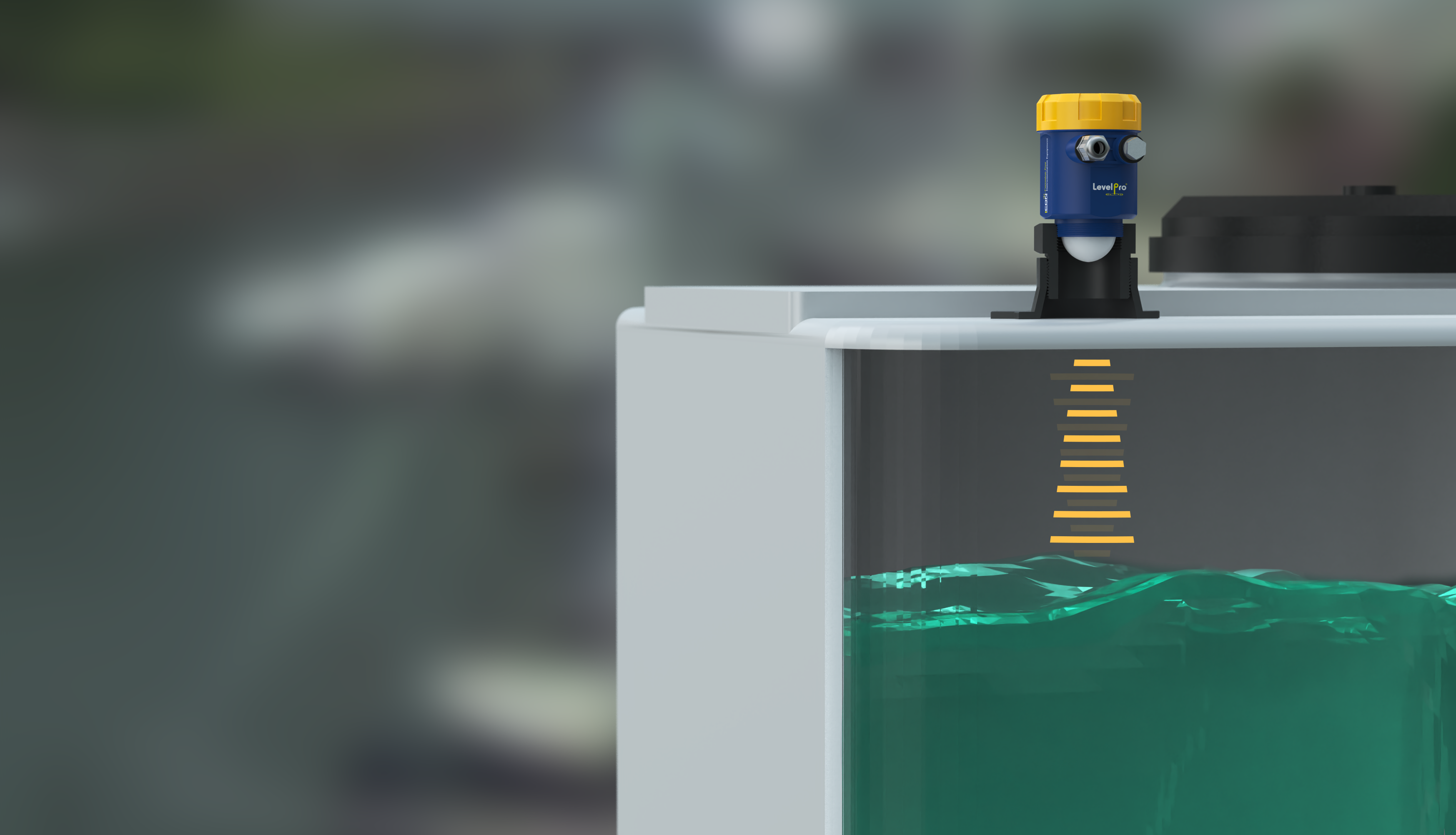

Radar Level Sensors:

Radar sensors provide non-contact measurement. Thus, ensuring accuracy in tanks containing corrosive or hazardous chemicals, without risk of exposure.

Float Level Sensors:

Float sensors are cost-effective for point level detection. Specifically, they are reliable for water or simple liquid monitoring applications.

Ultrasonic Level Sensors:

Using sound waves, these sensors measure levels accurately. Consequently, they are versatile for various tank sizes and configurations.

Key Features of Icon’s Agricultural Liquid Level Sensors

- Corrosion Resistance: Withstand aggressive chemicals using advanced materials.

- High Accuracy: Provide precise measurements essential for process optimization.

- Durability: Designed for extreme agricultural environments.

- Wireless Integration: Enable real-time monitoring and remote data access.

- Ease of Installation: Simple setup reduces downtime and installation costs.

Applications Across Various Agricultural Industries

- Irrigation Systems: Ensure consistent water levels in reservoirs.

- Fertilizer Tanks: Prevent overflows and ensure accurate dosing.

- Pesticide Storage: Monitor hazardous chemical levels safely.

- Hydroponic Systems: Maintain precise nutrient levels for optimal plant growth.

The Role of Wireless Technology in Liquid Level Sensing

Wireless technology revolutionizes agricultural liquid level sensing by offering remote monitoring, scalability, and reduced installation costs. Farmers can access real-time data from anywhere, enabling timely decision-making. Wireless sensors simplify system expansion, allowing seamless integration with existing infrastructure. These advantages improve operational efficiency and safety.

Ensuring Occupational Safety and Health Compliance

Icon’s sensors help farmers meet OSHA standards by preventing spills and leaks. Accurate monitoring reduces exposure to harmful chemicals, ensuring worker safety. Compliance with safety protocols protects against legal and financial liabilities.

Adhering to Environmental Protection Standards

Preventing chemical spills safeguards the environment from contamination. Icon’s sensors help farmers meet EPA regulations and promote sustainable farming practices. Reliable monitoring ensures responsible chemical usage, minimizing waste and environmental impact.

User Experiences: Real-World Benefits

Farmers using Icon’s sensors report fewer chemical spills, improved resource management, and enhanced safety. Real-time alerts enable quick responses to potential issues, reducing downtime and costs.

Selecting the Right Chemical Liquid Level Sensor

Consider these factors when choosing a sensor:

- Chemical Compatibility: Ensure materials resist corrosion.

- Measurement Type: Decide between continuous or point level detection.

- Environmental Conditions: Evaluate temperature, pressure, and turbulence.

- Installation Needs: Choose wireless options for remote or difficult-to-access areas.

Frequently Asked Questions

Why are wireless agricultural liquid level sensors important?

Wireless sensors provide remote monitoring, reduced installation complexity, and real-time alerts for operational safety.

What liquids can Icon’s sensors monitor?

They monitor water, fertilizers, pesticides, and other agricultural chemicals.

Are Icon’s sensors durable?

Yes, they are built with corrosion-resistant materials for long-term reliability.

Improve your farming efficiency with Icon Process Controls’ agricultural liquid level sensors. Visit our website to explore the perfect sensor for your needs. Contact us today for expert advice and solutions tailored to your agricultural applications.